When it comes to construction projects, framing plays a crucial role in providing structural support and stability. To achieve precise and efficient framing, professionals rely on powerful tools and reliable fasteners. In this comprehensive blog post, we will delve into the world of framing with a focus on the plastic collated framing nailer and 21-degree round head framing nails. Join us as we explore the versatility and benefits of these essential tools and fasteners, uncovering their role in achieving strong and durable framing connections.

The Power of a Plastic Collated Framing Nailer

A plastic collated framing nailer is a pneumatic tool designed specifically for framing applications. It offers unmatched power, speed, and precision, making it an indispensable tool for professional carpenters, contractors, and DIY enthusiasts. This type of nailer uses compressed air to drive nails into wood or other construction materials, allowing for quick and efficient fastening.

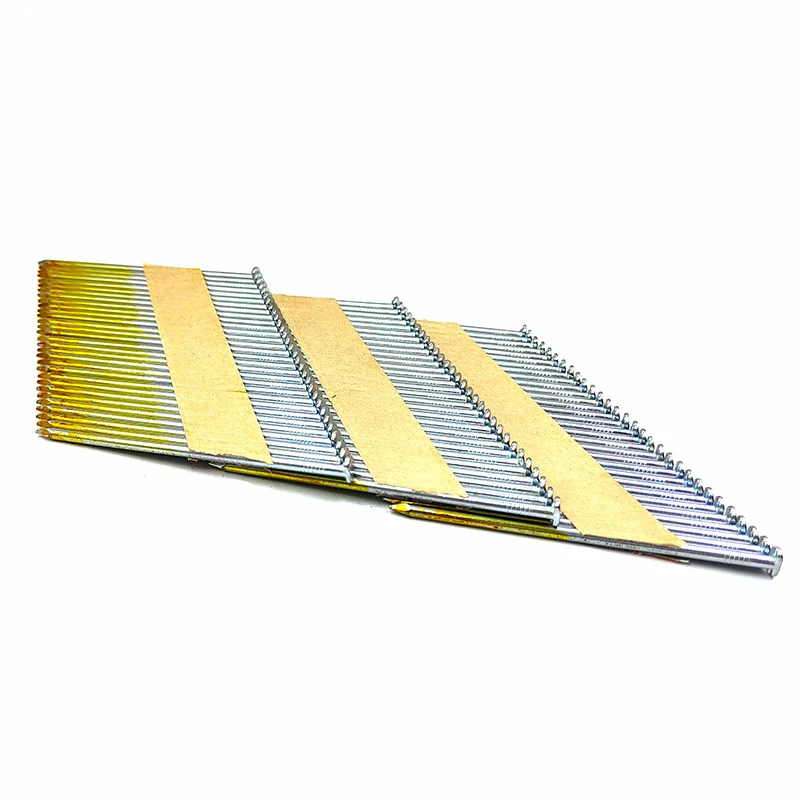

The plastic collation method ensures that the nails are held together by plastic strips, which provide added convenience during the nailing process. The collation strips allow for smooth loading and feeding of nails into the nailer, reducing downtime and increasing productivity. Additionally, the plastic collation prevents jamming or misfires, ensuring continuous operation.

21-Degree Round Head Framing Nails for Secure Connections

2 inch 21 degree framing nails are the preferred choice for most framing applications due to their strength and versatility. These nails have a round head that provides a larger bearing surface, resulting in a secure and stable connection between framing members.

One of the key advantages of 21-degree round head framing nails is their compatibility with various nailers, including plastic collated framing nailers. The 21-degree angle of the nail’s collation allows for a larger magazine capacity, reducing the frequency of reloading and increasing productivity on the job site.

These framing nails are available in different lengths, with the 2-inch 21-degree framing nails being a popular choice. The length of the nail depends on the thickness of the materials being fastened together. The 2-inch nails are commonly used for framing applications involving standard-sized lumber. They provide sufficient penetration and holding power, ensuring a strong and durable connection.

Benefits and Applications of Plastic Collated Framing Nailers and 21-Degree Round Head Framing Nails

Speed and Efficiency: The combination of a plastic collated framing nailer and 21-degree round head framing nails allows for rapid and efficient fastening. The nailer’s pneumatic power drives nails with precision, while the round head nails provide secure connections, saving time and effort on the job site.

Versatility: Plastic collated framing nailers can accommodate different nail sizes and collation types, including 21-degree round head framing nails. This versatility allows for a wide range of framing applications, including wall framing, roof truss assembly, floor joists, and more.

Strong and Durable Connections: The round head design of 21-degree framing nails provides excellent holding power, ensuring that framing members are securely fastened together. This strength is vital for structural integrity and longevity in construction projects.

Easy and Convenient Operation: Plastic collated framing nailers offer user-friendly features, such as adjustable depth settings and ergonomic designs, to enhance control and comfort during operation. The plastic collation of the nails simplifies loading and reduces the risk of jams, enabling smooth and uninterrupted work.

Time and Labor Savings: The combination of a plastic collated framing nailer and 21-degree round head framing nails significantly reduces the time and effort required for manual hammering. The pneumatic power of the nailer and the efficient design of the 16 gauge angled nails streamline the framing process, increasing productivity and reducing labor costs.