The ease of controlling and adjusting the pressure and filtration parameters of a filter press can vary depending on the specific design and features of the equipment. However, modern filter presses often incorporate user-friendly control systems and intuitive interfaces to facilitate convenient operation and adjustment of filtration parameters.

Here’s how controlling and adjusting pressure and filtration parameters are typically managed in filter presses:

- Control Systems: Many filter presses are equipped with advanced control systems that allow operators to monitor and adjust filtration parameters easily. These control systems may include touchscreen interfaces, push-button controls, or digital displays for convenient access to filtration settings.

- Pressure Regulation: Filter presses feature mechanisms for regulating the pressure applied during the filtration process. Hydraulic or pneumatic systems are commonly used to control the pressure exerted on the filter plates. Pressure regulators or valves enable operators to adjust the pressure level based on the specific requirements of the filtration application.

- Filtration Parameters: In addition to pressure, various other filtration parameters can be adjusted to optimize filtration performance. These parameters may include cycle times, flow rates, cake thickness, and washing or squeezing intervals. Control systems allow operators to set and modify these parameters as needed to achieve desired filtration results.

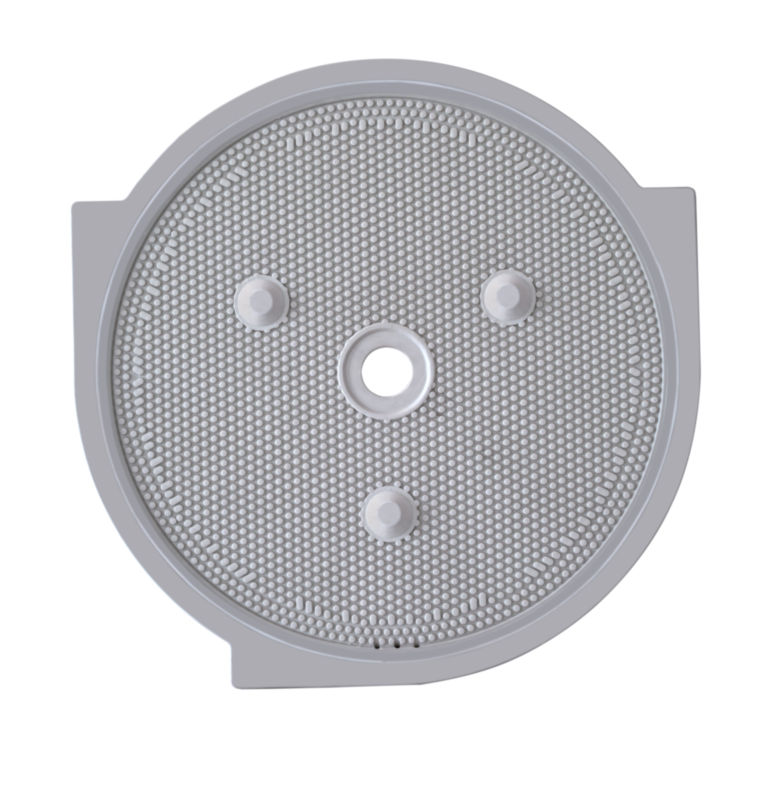

- Automatic Control: Some filter presses offer automatic or programmable control features that enable the equipment to adjust filtration parameters automatically based on predefined settings or feedback from sensors. filter press plates Automatic control systems enhance the efficiency and consistency of the filtration process by optimizing parameter settings in real time.

- Remote Monitoring and Control: Advanced filter presses may support remote monitoring and control capabilities, allowing operators to access and adjust filtration parameters from a centralized control room or via remote devices such as smartphones or tablets. Remote control functionality enhances convenience and flexibility, particularly in large-scale industrial operations.

- Training and Support: Manufacturers typically provide training and support to operators to ensure they are proficient in controlling and adjusting filtration parameters effectively. Training programs cover topics such as equipment operation, maintenance procedures, and troubleshooting techniques to empower operators to optimize filter press performance.

Overall, controlling and adjusting the pressure and filtration parameters of a filter press can be relatively straightforward with the right equipment and training. User-friendly control systems, automatic features, and remote monitoring capabilities contribute to ease of operation and enable operators to achieve optimal filtration results with minimal effort.